Background

In the sweeping plains of Kansas, Nebraska, and Ohio, McCarty Dairy operates a multi-location farm and processing plant that handles over 1.2 million gallons of milk daily. Built on four generations of dairy farming, the McCarty brothers moved west from Pennsylvania more than a decade ago, choosing to expand operations in areas with ample land and agricultural opportunities. What began as one family’s commitment to responsible, high-quality milk production has evolved into a modern agricultural enterprise—complete with its own processing facility, non-GMO crop management, and advanced data-driven techniques.

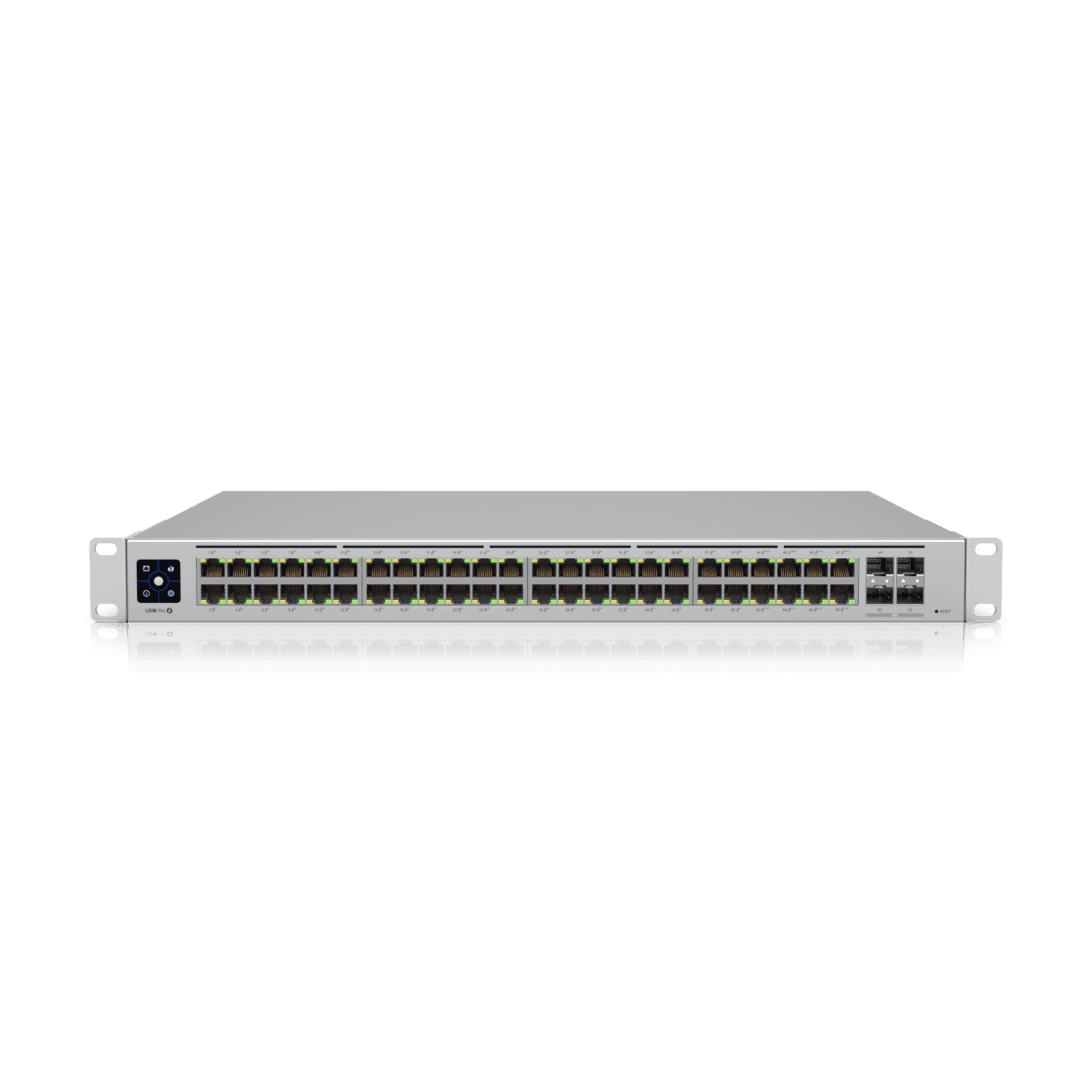

At the heart of McCarty Dairy’s evolution is technology. From a cloud-based feed management system to a pipeline of connected tractors and environmental controls, the farm leverages real-time data to optimize every facet of daily operations. To support this interconnected approach, McCarty Dairy has standardized on a robust network infrastructure—adopting cost-effective, user-friendly hardware solutions that handle everything from remote barns to office networks. According to Brett Bandy, the farm’s IT Director, “When you’re managing seven locations across three states with 24/7 operations, a solid network isn’t a luxury—it’s critical to our success.”